Organic matter and hydrogen peroxide diffuse from the main body of the solution to the vicinity of the active site on the surface of the catalyst for adsorption. Then, under the catalysis of the catalyst components, the hydrogen peroxide decomposes to generate OH, thus triggering a free radical chain reaction to oxidize and degrade the organic matter. Finally, the degraded products release from the catalyst surface and diffuse into the solution. However, no matter how the catalyst acts, the catalyst surface of the heterogeneous system is mostly subjected to a complex iron circulation process, thus maintaining the whole smooth catalytic oxidation reaction, in which the active species that cause oxidation are generated.

(1) The product adopts porous composite material as the catalyst carrier, has a high mechanical strength, and is doped with various catalytic components which are not easy to lapse, thus improving the catalytic activity and stability of the catalyst. High temperature sintering technology adopted can effectively ensuring high utilization rate and high adhesion of active components, reduces the loss rate of catalytic filler, prevents secondary pollution and prolongs the service life..

(2) By screening the carrier and active components of the catalytic filler through a large number of tests and engineering applications, the product can ensure sustained and efficient Fenton-like reaction catalytic effect.

(3) The product improves the catalytic activity of the catalyst and can be adapted to a wide pH range of the wastewater by screening suitable carriers and catalytic components..

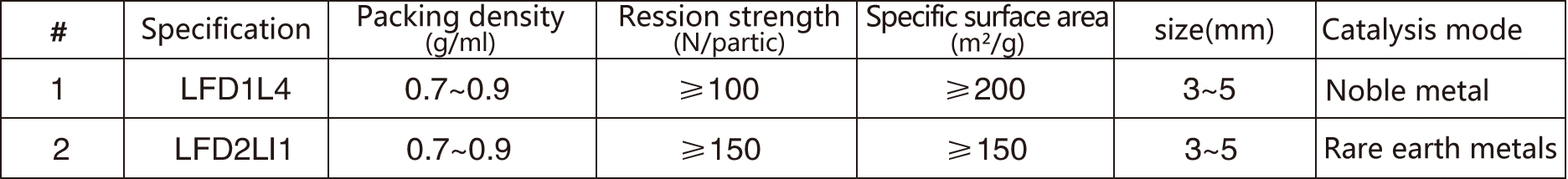

(4) The product by replaceing the addition of ferrous ions in the traditional Fenton oxization, the product avoids the generation of a large amount of iron mud, thus prevents secondary pollution, and greatly improving the defects for the traditional Fenton oxization.

● Printing and dyeing wastewater ● Landfill leachate ● Coal chemical wastewater

● Emulsion wastewater ● Pesticide wastewater ● Pharmaceutical wastewater

● Dye industrial wastewater