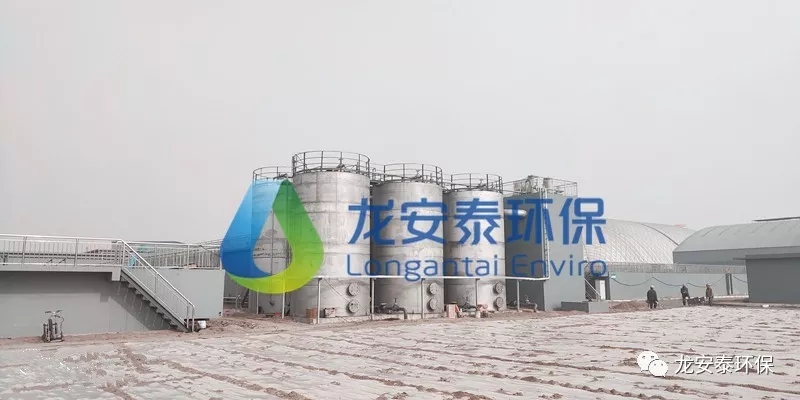

Application Case of LCO Ozone Catalytic Processes / advanced treatment for wastewater from a coal chemicals park in Shanxi

The advanced treatment project of a wastewater treatment plant in a coal chemicals park in Shanxi was completed in October 2018, and running well upon now. The designed volume of the project is 15,000m3/d; The composition of the wastewater received is complex. The pollutants in the wastewater contain dozens of inorganic and organic compounds, mainly are a large number of ammonium salts, thiocyanide, sulfide, cyanide, phenols, monocyclic and polycyclic aromatic compounds, as well as heterocyclic compounds containing nitrogen, oxygen and sulfur. It is a typical industrial wastewater containing refractory organic compounds.

LONGANTAI adopts " biochemical -LCO ozone catalysis +BAF" advanced treatment process for these kinds of wastewater. The highlight of the process is that the ozone catalytic oxidation technology is used as the back-end treatment, and the oxidation of ozone (oxidation potential 2.03V) is used to directly oxidize organic matters in water, or to oxidize and decompose macromolecular organic matters to small molecules, so that the organic matters are more easily degraded.Meanwhile, the process has an efficient removal ratio on chromaticity. By adding catalysts into ozone system, LONGANTAI can significantly improve the ability of the ozone system to generate hydroxyl radicals and improve the ability of ozone to directly oxidize organic matters, which will not affect the subsequent further biochemical treatment. At the same time, the technology can provide an oxygen source for the biofilter, thus producing synergistic effect. The ozone catalytic oxidation process is mature and stable, simple in process and convenient to operate; no chemical reagent is needed and no solid waste is generated in the whole process..

The effluent quality: COD<40mg/L, NH3-N<10 mg/L, TN<30 mg/L